As a kerb nerd, I'm going to talk about something which is a bit counter-intuitive this week and that is we should not use kerbs!

Actually, it's more specific than that because kerbs remain very useful components of our toolbox. The issue I am interested in this week is where a footway or cycle track meets a verge - a situation which on the whole doesn't actually need kerbs to be used.

It's perhaps worth reminding ourselves about what kerbs are for;

- Retain the edge of the top layers of a pavement,

- A demarcation between different areas or uses of a highway,

- To provide a check or channel for surface water management,

- To provide restraint to prevent vehicles leaving the carriageway.

For a footway or a cycle track meeting a verge, we might need to manage surface water, but we don't need demarcation (the edge of the surface does that), we don't need to restrain out of control people walking or cycling and it's pretty rare we actually need to retain the edge of the top layers of the pavement (the term used in its technical sense).

In my view, it is the first use which is where things go wrong and it is usually down to the specification being used. Footways and cycle tracks are usually fairly lightly constructed which reflects their users, although there are problems which motor vehicles are driven onto them.

When we build carriageways (roads), we are concerned with transferring loads from motor vehicles from the point where their tyres meet the surfacing, through the pavement layers to the weaker underlying soils.

The immediate surfacing material is of the highest quality and deals with sealing the pavement from water ingress and provids skidding resistance. In many cases, there will be two further asphalt layers which do structural work, but with cheaper materials which need to have a certain thickness to transfer the load as well as resist wheel rutting.

At sub base level in a flexible pavement, we are using a graded stone (or reclaimed crushed concrete and other materials) from 75mm in size down to dust (to a specification for good compaction) and then below that a capping layer of lower quality stone or other materials. The red triangle essentially shows that the load at the surface requires an ever larger area of the lower (and cheaper) layers to support the wheel which has a small contact area with the surfacing.

I hope you're still with me. The layers are varied and sometimes omitted such as the capping where the underlying soil is better at supporting loads. There are other designs of pavement available such as reinforced concrete and all manner of clever sheet materials to add strength, but let's keep it simple.

For footways and cycle tracks, we're generally not needing to transfer any loading from people - they simply don't cause damage as they walk or cycle along. We don't just leave grass or mud at the surface of course, a surfaced path is more comfortable to use and we can shed water off the surface (or we can use permeable materials and clever underlying materials and systems to deal with water).

In fact, the limiting issue is the ability to construct footways and cycle tracks in the first place because at the absolute minimum, we need to be able to use a roller (usually vibrating) to compact the sub grade and the layers above. In fact, I think all asphalt surfaces should be laid by machine unless it is localised repair or reinstatement. If we simply compacted surfacing on the soil below, it would just get bashed into the ground when we roll it, so we need a bit of sub base to give a minimum pavement depth (There are different types and classes of roller depending on what the situation is).

The other dimension is that top soil is no good for building paths on. It has organic materials which rot down leading to settlement and plant seeds or roots can grow through to the pavement - we need to be founding our paths on the subsoil which means a certain thickness of construction. Beyond that, we need to assess maintenance - how heavy will the street sweeper be that cleans the footway or cycle track? How likely are we to get maintenance vehicles using it? What is the likelihood of people parking on it (cars, vans or lorries)? A perfectly competently built path for only walking and cycling use can be destroyed in one sitting by an HGV being driven over it.

In the Design Manual for Roads & Bridges, there is a whole document around footway and cycle track pavement design which goes into detail of the options available based on the strength of the sub grade soil and the type of loading. I'll not go through the detail of this because I have given a flavour above but I'll pick on one of the combinations because it gets me back to kerbs. With decent ground conditions and no chance of over-run, the recommended specification is 20mm of asphalt surfacing, a 50mm asphalt layer below that (called the binder course) and a 100mm sub base - a total thickness of 170mm.

The standard edging kerb is 50mm wide and 150mm deep. In general terms, it will be laid on a 100mm concrete bed with a 100mm concrete surround - in other words, to a depth of 250mm. This is where it all goes wrong.

The photograph below shows some recent repair work to a shared-use path near where I live. It's not immediately obvious what's going on, but essentially the old surfacing was removed (which looked like two asphalt layers to me) and some of the edging kerbs were replaced.

In the photographs above and below you can see that for the replacement edging kerbs, a trench was dug and new kerbs laid on concrete. In some places new sub base was laid between the edging kerbs and the whole thing was resurfaced (badly).

Around 8 weeks later, there are signs of failure in terms of cracks along the path returning as well as dips forming in the new surfacing (photograph below). It's not a location where vehicles tend to get and hopefully me riding my Dutch bike isn't that heavy!

It's not an isolate case. Elsewhere along this road, there have been attempts to repair cracks in the shared-use path. The photograph below shows a repair where the edging kerbs were replaced within a trench. It has failed again with a new crack as well as the joint between the old and new surfacing opening up.

The photograph below is slightly different because the failure is in an area which the edge of the path was rebuilt following water main works. But, it's the same pattern of failure. The water company would have only replaced what it took out.

It's not easy to see what is going on, but the photograph below is a close up of the crack. At the top you can just make out the concrete backing which is helping to support the edging kerb, which is a nice little clue in the mystery.

Now, my area is built on London Clay which is notorious for moving about as it dries out and shrinks in the summer and then absorbs water and expands in the winter (and when frost penetration could be another problem). This means that whatever we do, we have to accept that paved surfaces might be impacted - worse where there are tree roots sucking water out of the ground. There is a limit to how deep anyone should dig to find a decent sub grade and around my way, it will be metres before you get something better which means we work with what we have.

In the photographs, the reason the crack isn't always straight (aside from the stone within the surfacing being irregular) is the lack of quality control on the edging kerb backing concrete - you can see the ragged line of this in the second photograph of this blog - they are wasting concrete and not keeping everything neat and tidy.

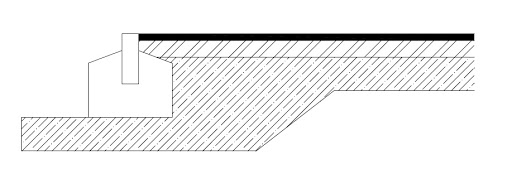

There are two ways to design this out. First, the edging kerb sitting on its concrete bed needs to be supported on sub base rather than directly on the soil which is created by the condition of having the minimum path thickness. In the image below, the sub base goes under the edging kerb and its concrete bed. It has to extend beyond to make sure it is fully supported.

It's not immediately obvious, but if you look at the photograph above, the three kerb lines are all supported on the sub base which extends beyond the two outer kerb lines.

The second way to design out the problem is to dispense with the kerb altogether which does run counter-intuitive to some people;

The photograph above is (yes you've guessed it) of a Dutch cycle track which hasn't got edging kerbs. You can clearly see the red surfacing and the black binder course below which is stepped out in support. The dotted lines you can see will have been left by the asphalt crew making sure the surface was properly set out. The photograph below shows the same cycle track without edgings on both sides.

Unless a kerb is needed to manage water or there is a local issue such as trying to prevent soil from an embankment washing onto the path, the lack of edging kerbs makes things far easier to maintain because there will be failures that need to be repaired from time to time. Vegetation management is important because if it encroaches, it can break the edge of the path and sometimes stop water flowing away (but that's no different to where you've a flush edging kerb anyway.

If the path is constructed from block paving or small slabs, then edging kerbs are used to restrain them, but can still be subject to movement which leads to failure in the paving, so it is no less important to get the detailing correct.

So, the next time you see a crack along an asphalt path in a bit from the edge, you'll know what has probably happened and how it should be fixed. Unfortunately, what will probably happen is the same mistake will be made again and people will be left scratching their heads.

...and don't use thin wooden edging on sandy rural foot/cycle paths. It looks lovely when new but as the path wears and develops muddy bits which people go round to avoid, the wood sticks up enough to derail unwary cyclists who catch it at an angle.

ReplyDeleteI saw the Twitter post on wooden edging and was thinking at the time why not just use no kerb - it's done that way on all our rural roads - so a timely piece for me (y)

ReplyDeleteColin Smith

Exactly how we built Sustrans Paths in 1980's-1990's at around a third of the cost for setting up concrete & timber edging kerbs - with a further lowering of costs when we went back to the traditional dry-bound macadam (without the bitumen), which if laid properly, with all motor vehicles banned, lasts for years.

ReplyDeleteA path profile that drains off to the sides with soil drawn in over the stone shoulders to provide a smooth edge. This delivers 2 key advantages

1) those with a visual impairment get the colour and texture contrast by walking with a foot on the path and a foot on the supported shoulder

2) a high output maintenance regime gets a clear verge to run down to deliver a path with no intrusive vegetation (or signs, seats, lamp posts) closer than 1 metre from path edge

Someday dear RH we'll have a feature on pavements perhaps? I ALWAYS try to ride my bike on a pavement, and have an especial fondness for a carriageway laid in tight bonded flat top stone setts around 1840, with an imperceptable camber that shoots even the lightest shower into the single course of in-line setts about 12mm lower than the main pavement as a beautifully functioning self flushing gulley. What's even better is that in 160 years with minimal maintenance - where a utility contractor hasn't wrecked it - no loose blocks, no potholes